Functional Food Production Wastewater Treatment

14 Nov, 2025VIET WATER provides complete wastewater treatment solutions for functional food manufacturing plants...

As environmental regulations become increasingly stringent, investing in a wastewater treatment system is mandatory for factories and industrial zones. However, to ensure stable and efficient operation that meets discharge standards, factory wastewater treatment system maintenance services have become an essential requirement.

So, what does wastewater treatment system maintenance include? Why is regular maintenance necessary? And how do you choose the right service to ensure efficiency and cost-effectiveness? Let’s explore these topics with Việt Water.

Industrial wastewater treatment systems are complex setups comprising mechanical equipment, electrical systems, biological processes, and various treatment technologies. During operation, these systems are exposed to wastewater with different chemical, biological, and physical characteristics.

Without regular maintenance and cleaning, the system is prone to:

Pipe and tank blockages

Decreased treatment performance (e.g., BOD, COD, TSS exceeding standards)

Malfunctioning of pumps, blowers, and sensors

Imbalanced microorganisms, leading to substandard effluent

These issues can cause production interruptions and potentially lead to fines or suspension of operations due to violations of environmental regulations.

A professional maintenance process typically includes:

Tank cleaning: Equalization tanks, settling tanks, and aeration tanks must be regularly desludged and cleared of debris.

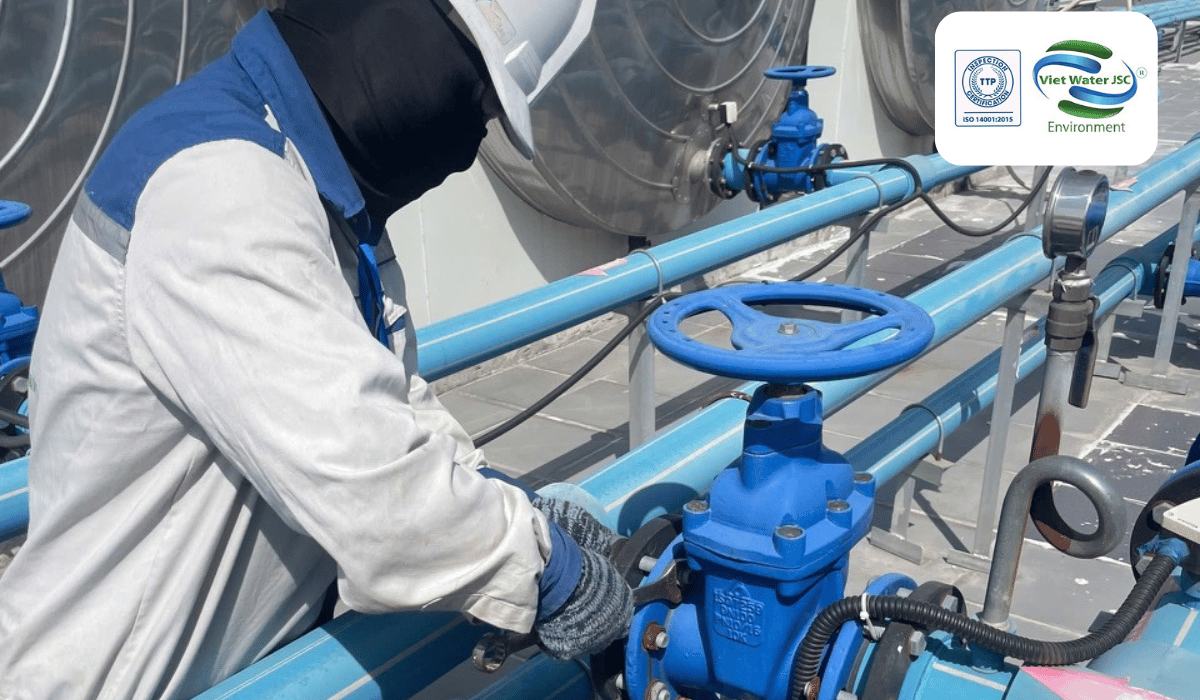

Mechanical equipment maintenance: Inspection and servicing of pumps, blowers, mixers—lubrication, seal replacement, and filter cleaning.

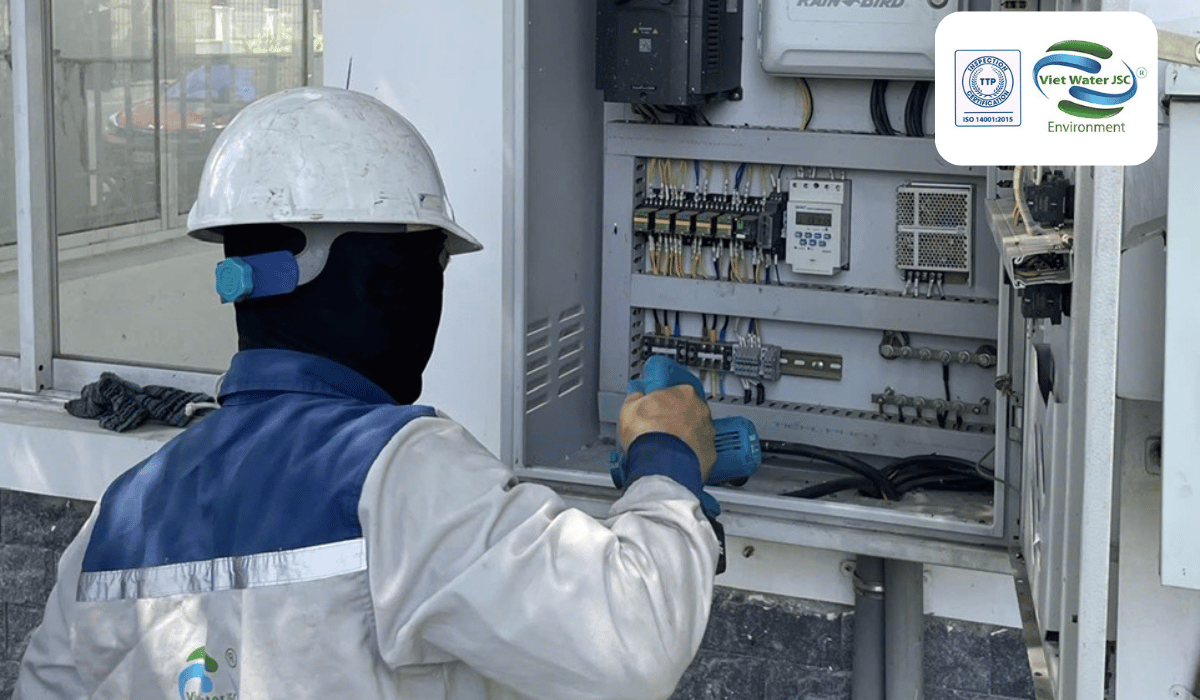

Electrical & control system calibration: Checking control panels, sensors, relays, and SCADA systems (if any).

Biological system inspection: Measuring SV30, DO, pH, and microorganism density.

Effluent water quality testing: Comparing with national discharge standards and recommending adjustments.

On-site survey of the current system

System evaluation report and maintenance proposal

Execution of maintenance tasks by qualified personnel

System testing and handover

Documentation and future maintenance recommendations

Monthly: Equipment cleaning, microbial inspection, water testing

Quarterly: Full mechanical and electrical maintenance, tank flushing

Annually: Electrical system testing, control cabinet calibration, environmental documentation updates

Each industry has specific wastewater characteristics, requiring tailored maintenance approaches.

Wastewater contains high organic load, odor, and grease.

Microbial control for BOD treatment

Grease trap system cleaning

Maintenance of sludge pumps and dosing pumps affected by fats

High concentrations of chemicals and colors cause equipment corrosion.

Coagulation-flocculation system maintenance

Mixer and chemical dosing pump inspections

Chemical reaction and oxidation tank cleaning

Odorous wastewater with high ammonia and nitrogen content.

Check aerobic and anoxic microbial systems

Clean air piping and blowers

Monitor NH₄⁺, NO₃⁻ concentrations for microbial balance

Extremely high or low pH and high TSS levels.

pH neutralization monitoring

Coagulation and sedimentation tank servicing

Inspection for equipment wear and tear

Regular membrane cleaning

Proper backwashing

Preventing biofilm buildup on membranes

Check automatic cycle programming

Clean mixers and sludge pumps

Adjust reaction–settling–draining times

Monitor DO, SV30, MLSS

Dose additional microorganisms when needed

Ensure even air distribution

Mixer and chemical pump maintenance

Regular tank flushing

Ensure correct chemical dosing and flow rates

Besides regular maintenance, Việt Water offers additional services to help factories optimize their wastewater treatment systems:

On-site operators per shift

Operation logs and immediate troubleshooting

Water sampling and reporting

Influent vs. effluent comparison

Stage-by-stage efficiency analysis

Cost-saving recommendations

Replace outdated equipment

Increase capacity to match production scale

Apply new technologies: membrane filtration, high-efficiency microbes

Maintenance reports

Periodic environmental monitoring reports

Regulatory compliance documentation

✔️ Ensure effluent meets QCVN standards

✔️ Extend equipment life, reduce replacement costs

✔️ Stable operation with minimal downtime

✔️ Transparent documentation, ready for inspections

✔️ Experienced engineering team offering on-site support

Wastewater treatment is not merely a technical requirement but a core element for sustainable production, legal compliance, and environmental responsibility. Choosing a factory wastewater treatment system maintenance service that is consistent and professional is a strategic decision for any enterprise.

🔧 If you need environmental consulting or OPERATION & MAINTENANCE SERVICES FOR WASTEWATER TREATMENT SYSTEMS, contact:

📞 Hotline: 0904506065

📍 Việt Water’s technical team is ready to inspect, advise on-site, and provide transparent, fast quotes!