Functional Food Production Wastewater Treatment

14 Nov, 2025VIET WATER provides complete wastewater treatment solutions for functional food manufacturing plants...

The food processing industry brings jobs to workers. Bring income to producers and the nation. Bring value to users. It can be said that this profession is very necessary for daily living needs. Besides the positives. Environmental issues are also the most worrisome issue is the problem of food processing wastewater treatment.

Food processing wastewater treatment is the treatment of wastewater arising from the following sources:

- Domestic wastewater of employees, from toilets, kitchen areas...

- Production wastewater includes water from preliminary processing, washing raw materials, cleaning machinery in the factory, cleaning processing equipment, cleaning the factory...

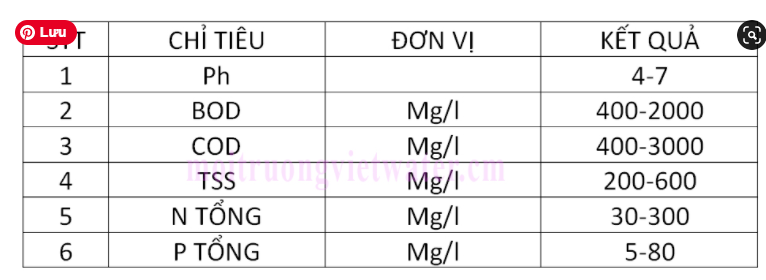

- The common characteristics of food processing wastewater is that it contains many organic compounds, high content of N, P, grease, and high residue.

- Depending on the specific production field of the food production industry. The composition of waste in the water will be different. And they depend on input materials, processing technology.

Contains high levels of Nitrogen and Phosphorus.

- With animal materials, wastewater contains high levels of protein, fat, and grease.

- The concentration of TSS, BOD, COD and bacteria components is quite high.

- Some types of food waste water contain salinity, color, starch.

Contains mainly organic ingredients and few harmful substances.

Composition of food processing wastewater

With the characteristics of the composition of Wastewater of food processing industry. we propose the biological wastewater treatment technology as the wastewater treatment technology of the food processing industry.

However, depending on input materials, some food processing fields have high pollution characteristics such as cattle slaughtering systems, seafood processing, fish sauce processing, etc.

Must use physico-chemical pretreatment methods such as flocculation, DAF flotation. Pre-treatment by mechanical methods such as: fine screens, sand settling tanks, etc. Some areas only need anaerobic and aerobic micro-organisms, but some need a combined anaerobic system.

Food Processing Wastewater Treatment Technologies.

Currently, there are many different technologies for the treatment of food processing wastewater. technologies will be separated or must be combined to handle, this depends on many factors. We will highlight some typical technologies.

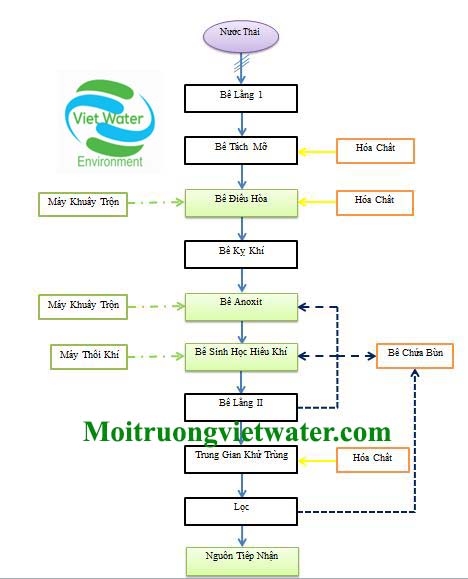

AAO technology treats food processing wastewater

Explain the technological process of food processing wastewater treatment

All wastewater generated from the food production and processing area will follow the collection system and be led to the sump. Before entering the sump, wastewater is led through the screen to prevent large-sized garbage (≥10mm). In order to avoid causing blockage of pipes and blockage of pumps during the operation of food processing wastewater treatment.

Clarifier

The task of the sand settling tank is to remove coarse and heavy residues such as sand, gravel, glass fragments, metal fragments, ash, coal chips, etc., in order to protect mechanical equipment that are prone to wear and reduce heavy deposits in the sedimentation tanks. post-processing.

Horizontal sand settling tank: There is a stream of water moving along the length of the tank. The tank has a rectangular cross section, usually with a sump located at the top of the tank.

Grease tank

Coupled with food processing wastewater. Depending on the type of industry, the input materials are different. but choose the method of fat separation so that it is effective and cost-optimized.

Flotation in the food processing wastewater treatment system is the most effective flotation tank. This method is often used to separate insoluble, poorly self-settling impurities from the liquid phase.

With high content, low adhesive capacity. If the self-adhesive time is long, the selection of a flotation tank is a mandatory measure.

The flotation process in the food processing wastewater treatment system is highly dependent on air bubbles. Start by bubbling small bubbles of air into the liquid phase. The gas particles adhere to the particles contained in and when the buoyant force gathers the bubbles and particles large enough, the particles will be brought to the surface. They then aggregate together into foam layers containing a higher concentration of particles than in the original liquid.

Conditioning Tank

Regulating flow, concentration, creating a stable working mode for the works behind. As a result, it reduces the size of the equipment and overcomes operational problems caused by flow fluctuations or overloads, improving the efficiency of the following processes.

Anaerobic Tank

Anaerobic biological filter tank has the effect of removing most of the pollutant components present in wastewater (BOD, COD, SS, ...).

The microbial sludge that is introduced initially is septic sludge, manure and specific activated microorganisms. Dead sludge from the anaerobic biological filter tank will be drained into the sludge tank by a sludge pump system.

Missing Tank

In the anoxic tank, with a variety of facultative microorganisms specialized for food processing wastewater treatment, it will treat the nitrogen content in the water, helping to convert energy and form new cells.

The amount of Nitrogen (Ammonia Nitrogen) in the wastewater mixes into it, causing a high content that will cause an imbalance in the nutritional composition (BOD/N/P). And cause poisoning or inhibiting microorganisms in food processing wastewater treatment systems.

Therefore, the process of oxidizing NH4 -> NO3 and denitrifying NO3 -> N2 is the inevitable reason to choose the above technology.

This is a mandatory process to reduce nitrogen in wastewater treatment technology

Aeration tank

Food processing wastewater after biological treatment lacks aeration. The large content of organic matter is reduced, from here the water is directed to the Aerotank tank. In the AAO technology system, food processing wastewater is treated. Aerotank tanks take place biological processes by aerobic microorganisms.

The amount of oxygen is maintained by the supply air from the blower. The microorganisms in the aerobic form (activated sludge) will decompose the remaining organic matter in the wastewater. The products after this process are simple inorganic substances such as: CO2, H2O... according to the following reaction:

Organic matter + Aerobic microorganisms → H2O + CO2 + New biomass +…

The efficiency of food processing wastewater treatment of the Aerotank tank is 75 ÷ 90%. This system depends on factors such as BOD, temperature, pH, oxygen concentration, sludge volume, etc.

Food processing wastewater after passing through the Aerotank tank, the biodegradable organic substances are completely removed.

Settling tank phase 2

In food processing wastewater treatment system. After the process of microbial treatment of activated sludge. Activated sludge and water mixed from Aerotank tank lead to and separated by settling tank. Microbiologically activated sludge will settle to the bottom, the clear water will pass through the mixing trough. The amount of sludge settles to the bottom, a part is recirculated back to the Aerotank tank and the anoxic tank. The residual sludge will be periodically discharged through the sludge tank.

Disinfection tank

Wastewater after sludge settling tank still contains a large amount of microorganisms. Therefore, sterilization is the last step in the treatment phase before being sent to the receiving source. The disinfection tank has the effect of mixing and diffusing disinfectant chemicals into the wastewater. The purpose is for wastewater and chemicals to have sufficient contact time. Disinfectant chemicals will destroy cells and kill pathogenic microorganisms.

Address of a reputable food processing wastewater treatment company

Viet Water JSC provides customers with optimal technology solutions, in line with the goal of EFFICIENCY and COST REDUCTION for investment and operation in food processing wastewater treatment.

You need to build a food processing wastewater treatment system with reasonable cost, stable operation, meeting discharge standards, and low operating costs.

The Company's wastewater source is a problem that needs to be solved to ensure environmental requirements.

Need to find a reputable environmental treatment company treat food processing wastewater and handle environmental problems.

The wastewater treatment system of the facility you own often has problems, the parameters in the domestic wastewater of food processing.

Contact Viet Water JSC for appropriate support and advice for your business. (Call for technical advice – 24/7 quote: 0904506065 – 0947999930).

CONTACT INFO:

VIET WATER JOINT STOCK COMPANY

Address: 339 Pham Van Bach, Ward 15, Tan Binh District, City. HCM.

Email: Info@vietwaterjsc.com

Website: vietwaterjsc.com – www.moitruongvietwater.com

Contact for consultation, quote (24/7) : (+84).904506065 – (+84).947999930

________Đặt lịch hẹn với chúng tôi