MBR FILTER - Deerfos (Korea)

25 Nov, 2021New generation Deerfos (Korea) filter with compact design for installation, stable operation. Connec...

TREATMENT OF WASTE GAS OF PAINT, SOLVENT

Viet Water provides customers with optimal technology solutions, in accordance with the lowest and most effective investment costs. Provide technical drawings, instructions and construction supervision for the items that the Investor can perform.

After design, construction, operation, etc. Viet Water will train and transfer technology completely to partners.

Contact Viet Water for a free quote, support and advice for customers. (Technical consulting support – 24/7 quote: 0947.9999.30 – 0904.506.065).

NEED

You are looking to install an exhaust gas treatment system for Paint Spraying Workshop, solvent with reasonable cost, stable operation, high quality, low operating cost.

The Company's emission source is a problem that needs to be solved to ensure environmental requirements.

The exhaust gas treatment system of your company is often having problems, the parameters in the exhaust gas after treatment are fluctuating and difficult to control.

Your customers apply environmental ISO to your products.

…

SOLUTION

How to have effective and standard solvent and paint emission technology, reasonable cost, stable operation, suitable for production scale? That's what investors are always interested in.

Understanding that problem, Viet Water Joint Stock Company has designed and built many different factories, built, installed, renovated and upgraded exhaust gas treatment systems. Now Viet Water offers different solutions depending on the existing premises, investment costs as well as the needs of the Investor to advise on individual cases for customers.

1. CHARACTERISTICS OF WASTE GAS OF PAINT, SOLVENT

Paint solution includes a film-forming agent, the task of this substance is to create adhesion, link the components in the paint, when applied or sprayed on the surface of the material, it will create solidity and help the paint have coverage. The next component is the volatile substance, which can have many different volatile substances such as water, organic solvents, soluble solvents, etc.

Paint dust is a synthetic chemical dust that is very toxic to the body. Paint dust contains many toxic components such as:

Lead has an anti-rust function, making colors brighter (especially red, orange, yellow and white) and speeding up the drying process of paint.

Mercury has preservative, anti-bacterial and anti-mosquito effects.

Organic solvents and part of the solvents are released into the environment as gases and liquids.

In addition, the use of pigments containing metal oxides, including toxic heavy metals, is also generated and released into the environment in the form of dust.

Based on the characteristic composition of the exhaust gas, we would like to introduce the following exhaust gas treatment methods: Treatment method: Using absorption method.

Photo: Spray painting room

2. SELECTION OF WASTE GAS TREATMENT TECHNOLOGY

The principles are based on:

Low investment cost.

Low operating and maintenance costs.

Environmentally friendly technology.

VIET WATER Joint Stock Company would like to introduce to customers the most effective emission treatment technology today, meeting the criteria of the business. Ensure the output emissions meet QCVN 20:2009/BTNMT – National technical regulation on industrial emissions for some organic substances.

TECHNOLOGY CHAPTER OF PAINT, SOLUTION GAS TREATMENT SYSTEM

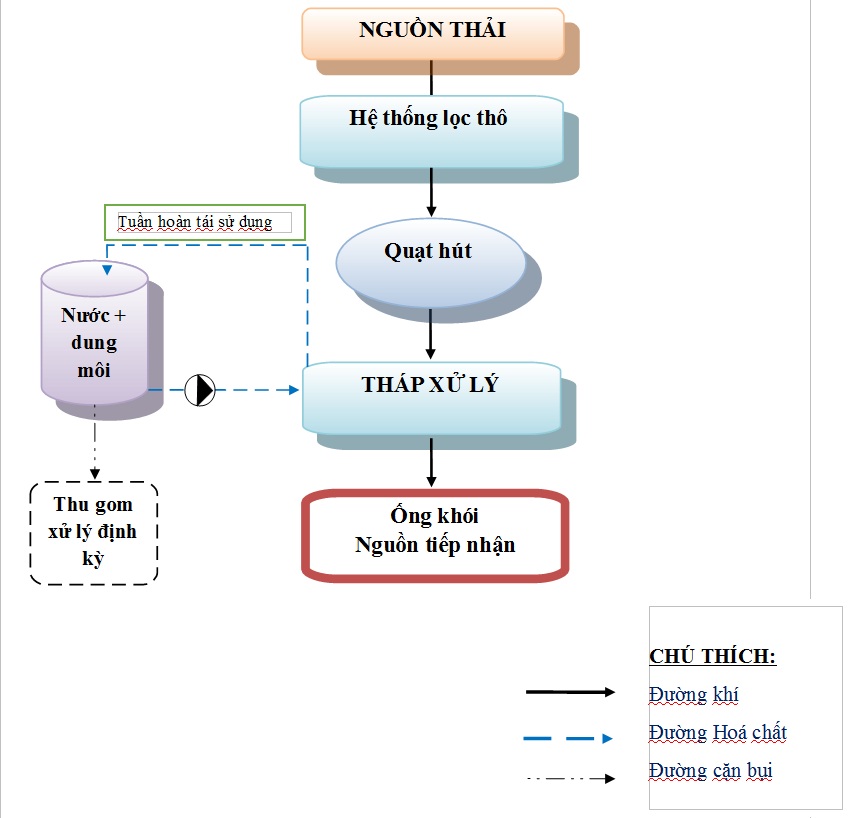

Paint dust emissions from the paint rooms will be collected and sent to the pre-filter system. The pre-filtration system uses a dry-solid material treatment method, to retain solvent vapors, paints with a large density and size. Filter media will be replaced periodically.

The exhaust gas after the pre-filtration treatment system will be pushed by the exhaust fan to push the main treatment tower air. The exhaust fan is for the purpose of bringing air through the treatment tower, helping the exhaust gas to have a design escape, avoiding the case of "air blockage, gas entrapment".

At the main treatment tower, the exhaust gas will be exposed to the absorbent solvent to treat the pollutant components present in the paint dust exhaust. The treated solvent will be collected back to the tank and continue to be recycled and reused.

Exhaust gas after treatment will meet the prescribed standards.

TECHNOLOGY ADVANTAGES:

3. PROGRESS – CONSTRUCTION MEASURES:

CONSTRUCTION METHODS:

Item of treatment tower: processed and manufactured at Viet Water Joint Stock Company's workshop, in an estimated time of 10-15 days. It is then transported to the installation site.

Item of equipment and technology pipeline: Directly installed and calibrated at the installation site, the working time is about 07 - 10 days

To avoid affecting the Company's operations, a detailed progress sheet and implementation plan will be sent to your company after the contract is signed.

CONTACT INFO:

VIET WATER JOINT STOCK COMPANY

Address: 339 Pham Van Bach, Ward 15, Tan Binh District, City. Ho Chi Minh

Email: Info@vietwaterjsc.com

Website: vietwaterjsc.com – www.moitruongvietwater.com

Phone: 02.862.724.888

Mobile : (+84).0947.9999.30 – (+84).0904.506.065