MBR FILTER - Deerfos (Korea)

25 Nov, 2021New generation Deerfos (Korea) filter with compact design for installation, stable operation. Connec...

PLANT WASTE WATER TREATMENT

Viet Water JSC provides customers with optimal technology solutions, in line with the goal of EFFICIENCY and COST REDUCTION for investment and operation.

TYPICAL PROJECTS:

Electroplating wastewater treatment system Cho Lon Plastic Company Factory - City. HCM.

Water treatment system Gen Bright Light Bulb Co., Ltd. - Long An.

…

NEED

You need to build a wastewater treatment system for electroplating, production, etc. with reasonable cost, stable operation to meet discharge standards, and low operating costs.

The Company's wastewater source is a problem that needs to be solved to ensure environmental requirements.

Need to find a reputable environmental treatment company to treat electroplating wastewater, ... and handle environmental problems.

The electroplating wastewater treatment system of your establishment often has problems, the parameters in the wastewater from raising pigs, cows, etc., after treatment, fluctuate and are difficult to control.

…

Contact Viet Water JSC for appropriate support and advice for your business. (Call now for technical advice – quote 24/7: 0904506065 – 0947999930)

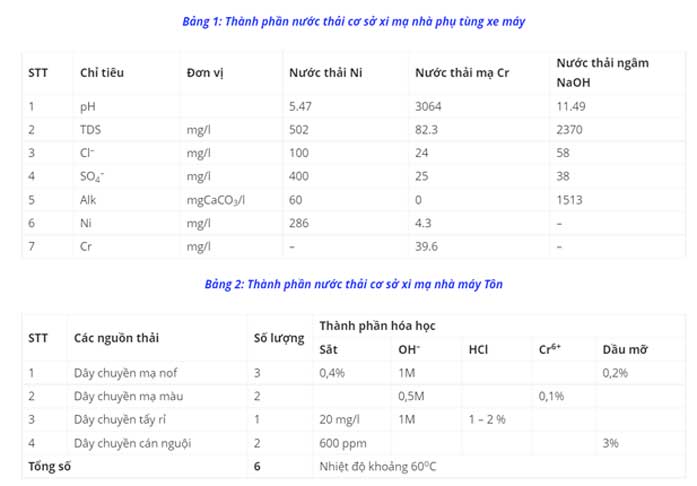

1. COMPOSITION OF CHARACTERISTICS OF SILVER WATER

Wastewater from the plating plant has a wide range of concentrations and pH ranging from very acidic 2-3, to very alkaline 10-11. The common characteristic of plating industry wastewater is that it contains high levels of inorganic salts and heavy metals. Depending on the metal of the plating layer, the source of pollution can be Cu, Zn, Cr, Ni, etc. and also depending on the type of metal salt used, the wastewater contains toxins such as cyanide, sulfate, ammonium, etc. chromate,…

Organic substances are rarely found in plating wastewater, the main part is flocculating agent, surfactant, etc., so BOD, COD are usually low and not subject to treatment. The main treatment objects are inorganic ions, especially heavy metal salts such as Cr, Ni, Cu, Fe, etc.

Wastewater should be separated into 3 separate streams:

– Concentrated waste solution from dipping tanks, immersion tanks.

– Equipment washing water with medium dirt content (metal salts, grease and soap, etc.

– Dilute washing water.

For safety and ease of handling, the chromic acid stream and the cyanide stream should be separated. Pollutants of electroplating wastewater can be divided into the following groups:

o Toxic pollutants such as cyanide CN-, Cr (VI), F-, etc.

o PH-altering pollutants such as acid and alkaline flows

o Contaminants that form suspended residues such as hydroxides, carbonates and phosphates

o Organic pollutants such as grease, EDTA...

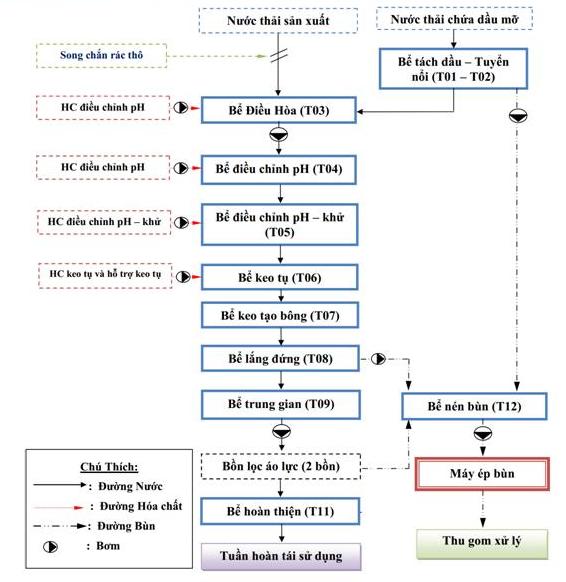

2.TECHNOLOGY CHART:

We would like to introduce to our customers the technology of plating wastewater treatment by chemical and physical treatment methods as follows:

Technology explanation:

Wastewater treatment technology proposed by Viet Water Company ensures treatment efficiency, wastewater after treatment meets the discharge standards.

The wastewater treatment system is operated automatically, in addition, there is a manual operation mode when there is a technical problem.

Oil separator – flotation tank (T01-T02):

Oil separator – flotation tank is designed to separate floating and sediment. In wastewater with part of sediment and floating sediment, the tank helps to collect sediment at the bottom of the tank and sediment floating on the surface.

In the tank, there is a diffusion system of dissolved gas into the water, which helps the process of separating the suspended particles that are not separated by the settling process to be separated from the wastewater in the form of floating sediment.

In the tank, a conveyor belt removal system is arranged to help the sludge collection process to be effective. Sedimentation and floating sediment will be pumped to the Sludge Compression Tank (T12) for treatment.

The water after flotation will be flowed to the conditioning tank.

Conditioning tank (T03):

Water from different stages of the plant is collected to the conditioning tank (T03). The air-conditioning tank is responsible for stabilizing the flow and concentration of pollutants present in the wastewater. Here, wastewater is supplemented with pH adjustment chemicals to serve the next treatment. Water from the conditioning tank will be pumped to the pH adjustment tank (T04)

pH adjustment tank (T04):

Wastewater here is supplemented with chemicals by metering pumps to adjust pH to the appropriate level. In the tank, a stirring motor is arranged with a stirrer to ensure the best pH adjustment of the wastewater.

pH-reducing tank (T05):

Waste water flowing from T04 sang tank will be supplemented with chemicals to treat heavy metals in wastewater, then the wastewater will be pH adjusted. Right at the position of the tank outlet pipe, coagulant chemicals will be added. Water will be flowed to Coagulation Tank – T06.

Coagulation tank (T06):

Wastewater is filled with coagulant chemicals and flocculation aids, where the flocculation process occurs . pollutants present in the wastewater. In the tank, a stirring motor is arranged with a stirrer to ensure the best flocculation effect.

Cotton forming tank (T07):

Wastewater is stirred at a slow speed to form large flocs before flowing to the Settling Tank – T08.

Settling tank 1 (T08):

Settling tank 1 is designed in the form of a vertical settling tank, the flocs containing pollutants in the wastewater will be settled to the bottom of the tank by gravity, the clear water will be collected through the settling trough on the top of the tank.

The settled sludge will be pumped to the sludge compaction tank - T12, in the tank there is a motor and sludge vane to assist in the collection of settled sludge. The floating sediment will be collected by the floating sludge collector.

The water after settling will flow through the intermediate tank – T09.

Intermediate tank (T09)

The intermediate tank is responsible for storing water to pump inter-cooling towers, in order to reduce the temperature of wastewater to 30-350C.

Pressure filter tank (T10):

In the filter tank, filter materials are arranged capable of removing suspended substances of small size and density in water after physico-chemical and physical treatment that cannot be removed during the settling process, and at the same time remove part of compounds containing heavy metals dissolve in wastewater and deodorize, color.

The treated water is stored in the finishing tank (T11) and reused for production if necessary.

Sludge compaction tank (T12):

The sludge from the wastewater treatment stages will be pumped to the sludge compaction tank (T12), the sludge compaction tank is used to reduce the volume and moisture of the sludge by separating the excess water in the sludge. Excess water will be returned to the conditioning tank, the sludge after compression will be pumped to the Screw Slurry Press.

End of processing.

3. CONSTRUCTION SOLUTION

Currently, there are many methods of construction of wastewater treatment systems. Depending on the actual situation at the enterprise, we have different system layouts. Viet Water would like to present some popular construction methods today.

Construction method of bricks, reinforced concrete: This method is quite classic, but still popular in many cases. Depending on the needs, we can build full sound or half floating half sound.

Advantages :

Durable and solid.

Universal should be easy to build, no need for environmental expertise.

Build many different shapes, flexible.

Construction methods of steel, composite, PVC: These are some improved construction methods for businesses that do not have much construction area and want to save costs.

Hình ảnh: Hệ thống xử lý nước thải bằng thép, composite, nhựa PVC

Ưu điểm :

Không tốn nhiều diện tích, nhỏ gọn.

Chi phí giảm đáng kể.

Linh hoạt trong việc di dời và tăng module.

Thi công nhanh.

THÔNG TIN LIÊN HỆ:

CÔNG TY CỔ PHẦN VIỆT WATER

Địa chỉ :339 Phạm Văn Bạch, Phường 15, Quận Tân Bình, Tp. Hồ Chí Minh

Email :Info@vietwaterjsc.com

Website : vietwaterjsc.com – www.moitruongvietwater.com

Liên hệ tư vấn, báo giá (24/7) : (+84). 0904506065 – (+84). 0947999930