Design Process of a Wastewater Reuse System

This article presents the design process of a wastewater reuse system, based on practical experience and techn...

As freshwater resources become increasingly scarce, water supply costs continue to rise, and environmental compliance requirements grow stricter, the Wastewater Reuse System has emerged as a strategic solution for industrial facilities, industrial parks, and commercial buildings.

Instead of treating wastewater solely for discharge compliance, many enterprises now invest in advanced wastewater reuse systems to reclaim treated effluent for suitable internal applications. This approach not only reduces operating costs but also strengthens environmental performance and long-term sustainability.

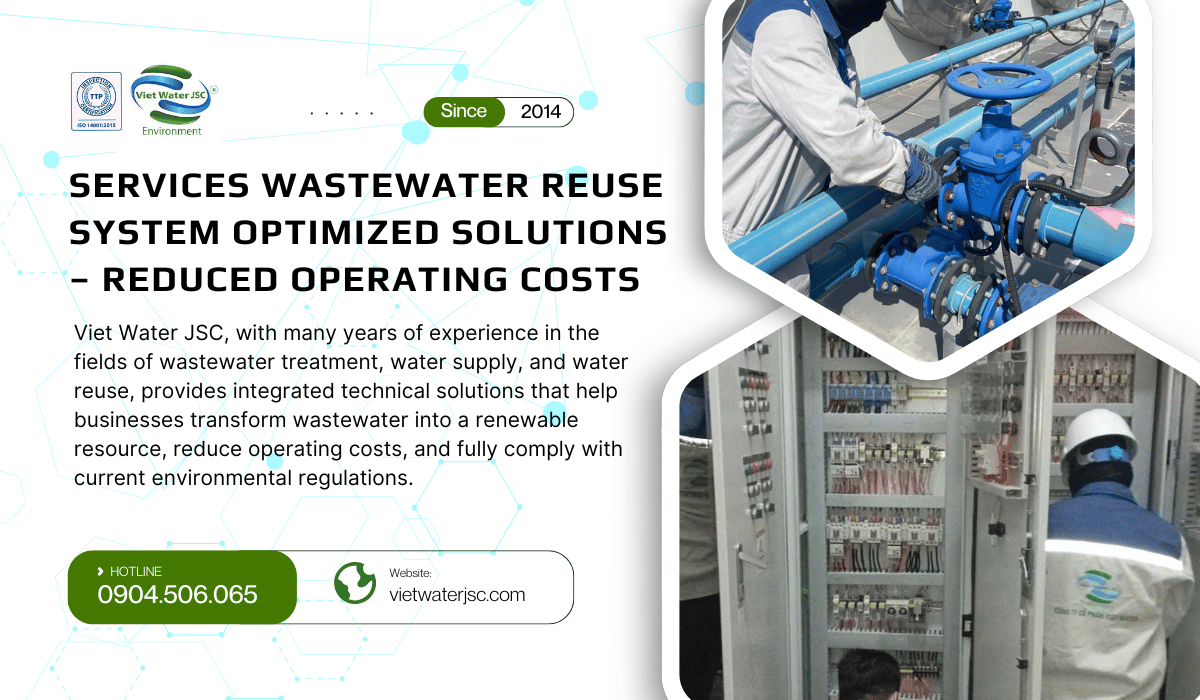

With extensive experience in wastewater treatment engineering, Viet Water JSC delivers customized wastewater reuse systems designed to meet industry-specific needs while ensuring operational efficiency and regulatory compliance.

A Wastewater Reuse System is an integrated treatment solution that further upgrades treated wastewater quality, enabling it to be safely reused for defined purposes instead of being fully discharged into the environment.

Unlike conventional wastewater treatment systems that focus only on meeting discharge standards, wastewater reuse systems incorporate advanced treatment stages, such as:

Ultrafiltration (UF)

Membrane Bioreactor (MBR)

Reverse Osmosis (RO), when high-quality water is required

UV or Ozone disinfection

Online monitoring and quality control

These systems are engineered to produce reclaimed water suitable for various non-potable or process-related applications.

The growing adoption of wastewater reuse systems is driven by several key factors:

Rising freshwater supply and discharge costs

Seasonal water shortages and supply instability

Stricter environmental regulations and permits

ESG, CSR, and sustainability reporting requirements

Increasing expectations from international clients and investors

By implementing wastewater reuse, enterprises gain both economic and environmental advantages.

Depending on application and system design, wastewater reuse can reduce freshwater demand by 30–70%, especially in water-intensive industries such as food processing, seafood, textiles, and manufacturing.

Reducing discharge flow helps stabilize wastewater treatment operations, minimizes regulatory risk, and enhances environmental compliance.

Reclaimed water ensures continuity during droughts, peak production periods, or temporary water supply interruptions.

A wastewater reuse system is a strong asset in ESG evaluations, environmental audits, and sustainability disclosures.

Based on project experience, Viet Water JSC designs wastewater reuse systems for:

Food & beverage processing plants

Seafood processing and livestock facilities

Textile, plating, and chemical industries

Industrial parks and manufacturing clusters

Commercial buildings and residential complexes

Each system is custom-engineered, avoiding unnecessary investment while ensuring optimal performance.

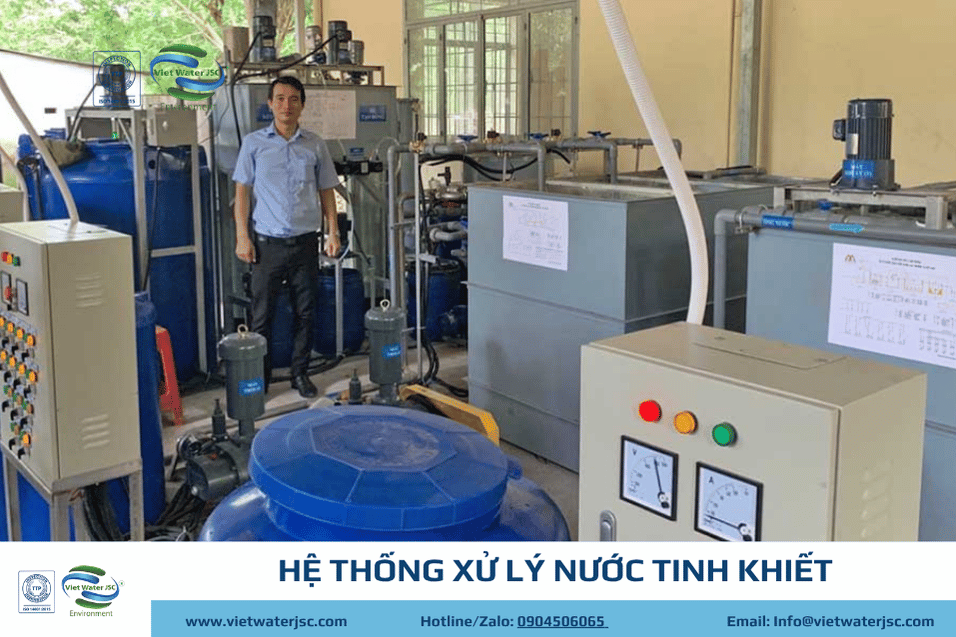

A standard system generally includes:

MBR, MBBR, or SBR processes

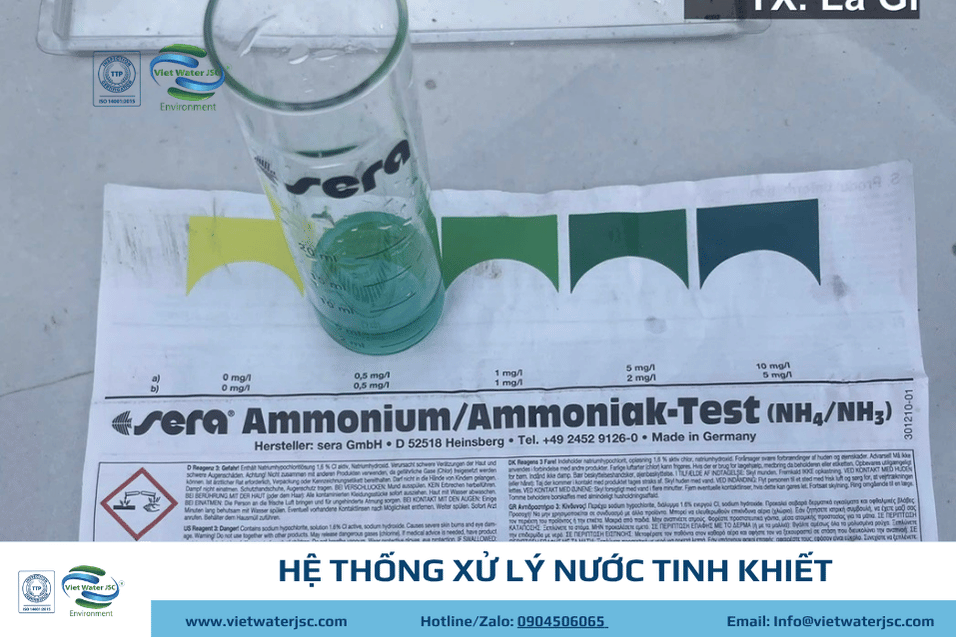

Removal of COD, BOD, ammonia, and nutrients

UF membranes

Activated carbon filters

RO systems for high-purity water demands

UV disinfection

Ozone treatment

Chlorination (if required)

Reclaimed water storage tanks

Booster pumps

Dedicated reuse pipelines

Online sensors for pH, turbidity, TDS

Automated control and monitoring systems

Design philosophy:

“Meet reuse requirements precisely—no excessive technology, no wasted investment.”

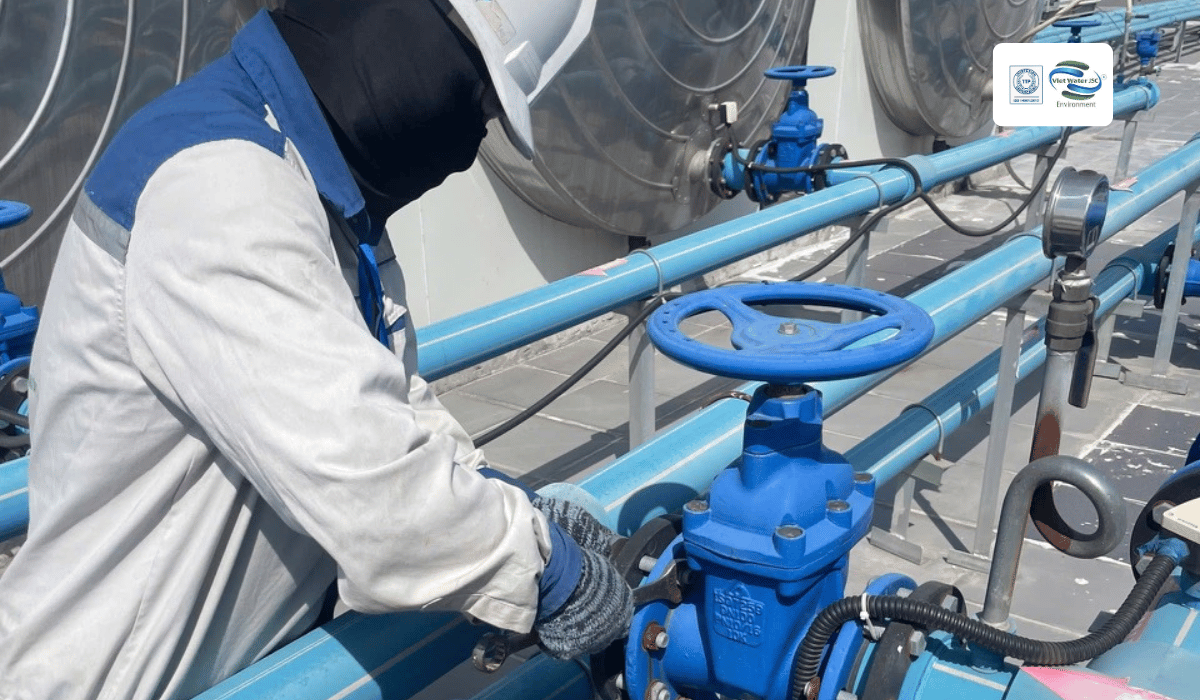

A typical operational sequence includes:

Collection of wastewater and biological treatment

Advanced filtration to remove fine solids and microorganisms

Final disinfection

Storage of reclaimed water

Distribution to designated reuse points

Continuous water quality monitoring

Each stage is carefully calculated based on flow rate, pollutant load, and reuse objectives.

Not all reuse applications require the same water quality. Viet Water JSC classifies reuse levels as:

Landscape irrigation and road washing

Cooling towers and heat exchange systems

Industrial process water

Boiler feed water (combined with RO systems)

Each reuse level has distinct design criteria and investment costs.

Wastewater reuse systems must comply with:

Relevant Vietnamese discharge and reuse regulations

Internal corporate water quality standards

Environmental permits and approvals

Client or investor-specific technical requirements

Viet Water JSC provides full technical consulting and regulatory support throughout the project lifecycle.

The cost of a wastewater reuse system depends on:

Required reuse quality

Treatment capacity

Selected technologies

Automation and monitoring requirements

In practice, many projects achieve payback within 2–4 years through reduced freshwater and discharge expenses.

Proven experience across multiple industries

Tailored solutions aligned with real operational needs

EPC services from design to commissioning

Environmental permitting and compliance support

Long-term operation and maintenance assistance

Site survey and wastewater analysis

Technology selection and system proposal

Detailed engineering and cost estimation

Construction and installation

Commissioning and performance testing

Handover and operator training

A Wastewater Reuse System is not only an environmental solution but a strategic investment that helps enterprises reduce costs, secure water resources, and achieve sustainable growth.

Viet Water JSC is committed to delivering reliable, efficient, and future-ready wastewater reuse solutions tailored to your business needs.

This article presents the design process of a wastewater reuse system, based on practical experience and techn...

This article outlines the construction process and critical considerations for wastewater reuse systems, based...

This article presents a practical guide to operating wastewater reuse systems, based on real operational exper...

Maintenance and servicing of wastewater reuse systems are not optional—they are essential for ensuring stable...

Upgrading wastewater reuse systems is not only a technical improvement but a long-term economic and environmen...