Boiler gas treatment

BUILTER GAS TREATMENT

Viet Water provides customers with optimal technology solutions, in accordance with the lowest and most effective investment costs. Provide technical drawings, instructions and construction supervision for the items that the Investor can perform.

Photo: Boiler burning area

After design, construction, operation, etc. Viet Water will train and transfer technology completely to partners.

Contact Viet Water for a free quote, support and advice for customers. (Technical consulting support – 24/7 quote: 0947.99999.30 – 0904.506.065)

NEED

You are looking to install an exhaust gas treatment system that burns wood, coal, etc. with reasonable cost, stable operation, high quality, and low operating costs.

The Company's emission source is a problem that needs to be solved to ensure environmental requirements.

The exhaust gas treatment system of your company is often having problems, the parameters in the exhaust gas after treatment are fluctuating and difficult to control.

Your customers apply environmental ISO to your products.

1. BOILER GAS PROPERTIES

Table of emissions properties based on the calculation of the pollution coefficient of wood-burning boilers in industry.

In fact, the values will be different from time to time.

Based on the typical composition of the wood-burning furnace, coal, etc., Viet Water would like to introduce the following exhaust gas treatment methods:

Treatment method: Use absorption method.

2. SELECTION OF WASTE GAS TREATMENT TECHNOLOGY

- The principles are based on:

- Low investment cost.

- Low operating and maintenance costs.

- Environmentally friendly technology.

VIET WATER Joint Stock Company would like to introduce to customers the most effective emission treatment technology today, meeting the criteria of the business. Ensure that the output exhaust gas meets QCVN 19: 2009/BTNMT – National technical regulation on industrial emissions for dust and inorganic substances.

TECHNOLOGY CHAPTER OF BUILDER WASTE GAS TREATING

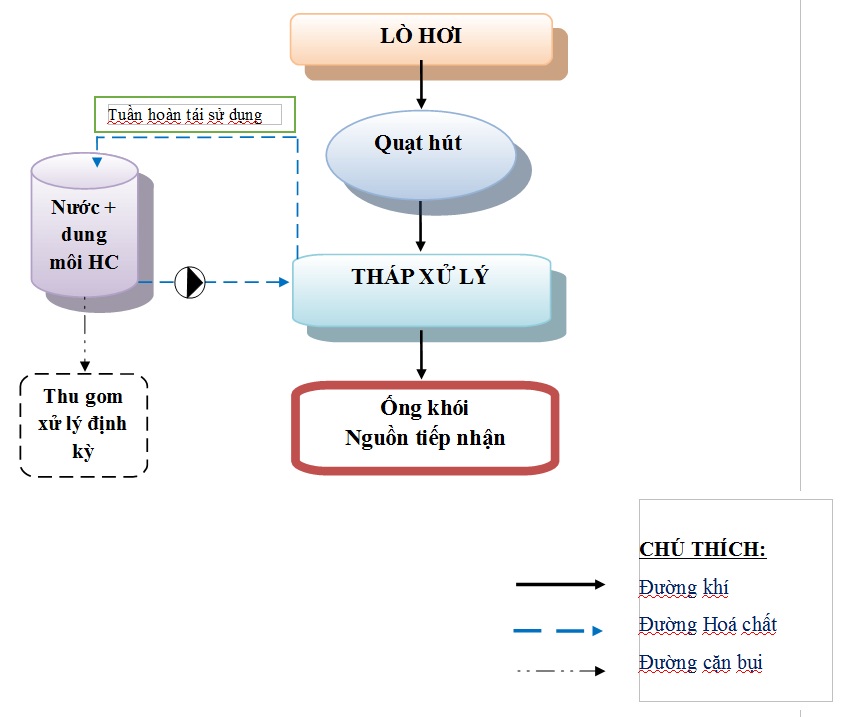

The exhaust dust from the boiler will be collected and brought to the pipeline system. Exhaust gas will be pushed by the exhaust fan to the Main Treatment Tower. The exhaust fan is for the purpose of bringing air through the treatment tower, helping the exhaust gas to have a design escape, avoiding the case of "air blockage, gas entrapment".

At the main treatment tower, the waste gas will be in contact with water to cool the exhaust gas and increase treatment efficiency. When discharged after cooling, it will be in contact with absorbent solvents to treat the pollutant components present in the flue gas of the incinerator. The treated solvent will be collected back to the tank and continue to be recycled and reused.

Exhaust gas after treatment will meet the prescribed standards.

TECHNOLOGY ADVANTAGES:

Save on initial investment costs.

Save operating and maintenance costs for the system.

The system ensures automatic and continuous operation.

Simple and efficient operation.

Suitable for construction site.