MBR FILTER - Deerfos (Korea)

25 Nov, 2021New generation Deerfos (Korea) filter with compact design for installation, stable operation. Connec...

Dust handling (AEROSOL)

Viet Water provides customers with optimal technology solutions, in accordance with the lowest and most effective investment costs. Provide technical drawings, instructions and construction supervision for the items that the Investor can perform.

After design, construction, operation, etc. Viet Water will train and transfer technology completely to partners.

Contact Viet Water for a free quote, support and advice for customers. (Technical consulting support – 24/7 quote: 0947.99999.30 – 0904.506.065)

NEED

You are looking to install a waste gas treatment system for wood processing workshop, cement dust, ceramic tiles, steel dust, dust from the production process, etc. with reasonable cost, stable operation, high quality, low operating costs.

1. INTRODUCTION

Dust is the general name for solid particles as small as a few micrometers to half a millimeter in diameter, which settle down by their own weight but can remain suspended in the air for some time. Larger particles can be called sand or gravel. When dust is strongly dispersed in air or gases in general, the mixture of gas and dust is called a solid aerosol.

Aerosols are generated during grinding, agglomeration and various chemical reactions. Under the action of gas or air currents, they become suspended.

Aerosol classification by size:

2. DUST TREATMENT METHODS

a. Dry treatment method

This method usually has the following processing equipment:

Equipment for collecting dry dust according to the principle of centrifugal force: Cyclone.

Cyclone is used to filter dust of large density and size such as wood dust, cement, ceramic tiles, steel dust, non-adhesive dust, etc.

Cyclone dust treatment (aerosol)

Dry dust collector by gravity method: Dust settling chamber.

Dust settling chamber is mainly used to filter coarse dust particles, with density and size greater than 60mm, large initial concentration, gas moving with small velocity (<1÷2), sticky dust. high stickiness.

Image: Dust settling chamber

Dry dust collector according to the principle of inertia force: Dust settling chamber with reflector wall.

Dust settling chamber with reflective wall filters dust of large density and size or dust with high adhesion.

Equipment According to the principle of capture adhesion of the filter material: Dust filter cloth bag.

Dust filter cloth bag is used to filter small, heterogeneous and non-adhesive dust.

Image: Dust settling chamber with reflector

Dust filter cloth bag system

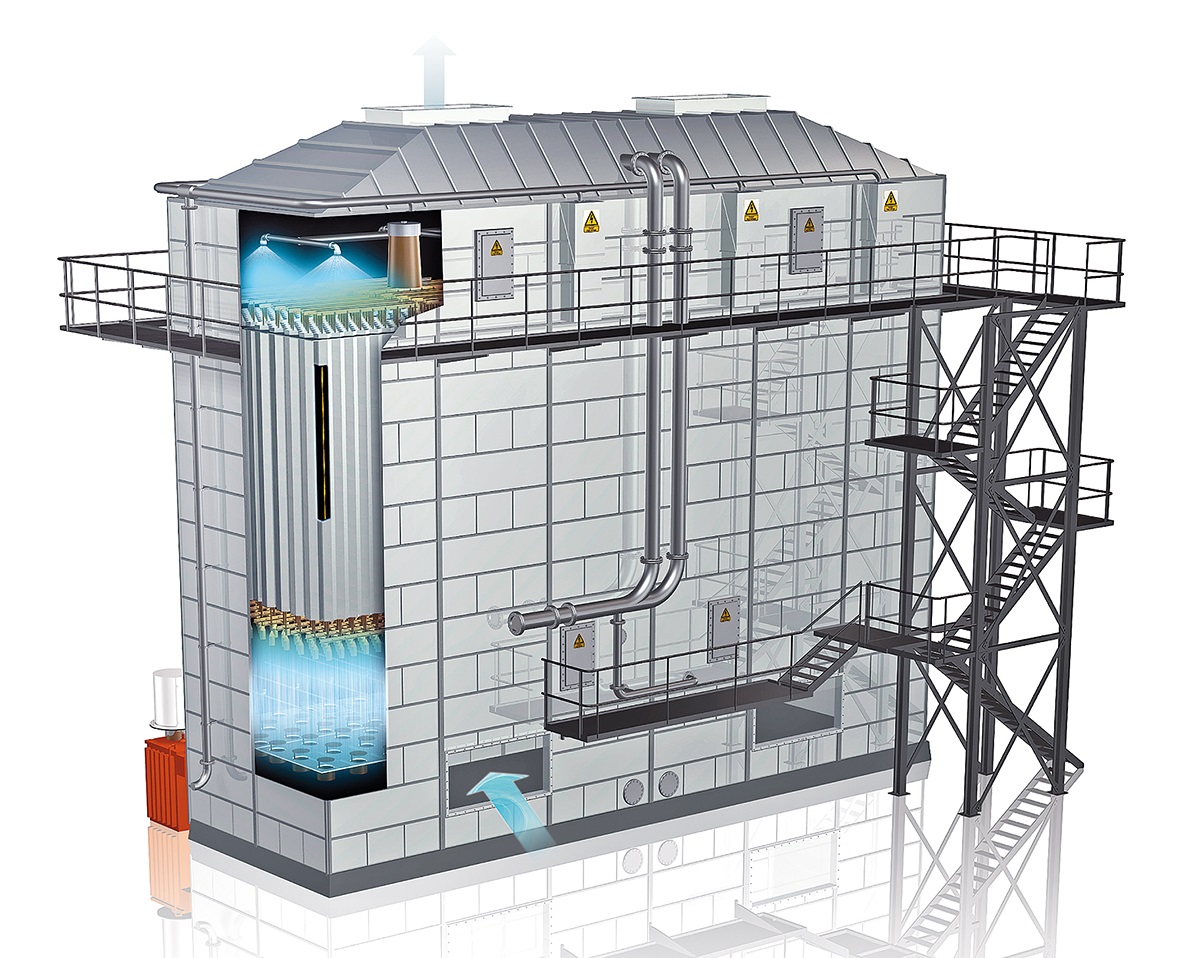

b. Wet treatment method

Wet dust treatment method is a contact method between the liquid phase and the gas phase, based on the principle of contacting the dust-carrying gas stream with the liquid, the dust in the gas stream is retained by the liquid and discharged in the form of sludge. .

The method of dust filtration by a wet-type dust collector gives very high dust filtration efficiency. The commonly used liquid is water, in some cases it is necessary to handle toxic gases, especially other types of solvents can be used with the ability to absorb.

Wet dust filter equipment is used when: Need to clean fine dust with relatively high efficiency, treat dust filter and remove harmful gas, use to cool exhaust gas.

Model of processing equipment using wet method

c. Electrostatic filter method

Electric dust filter equipment includes: Metal wire and metal pipe. A smooth metal wire of small cross-section is stretched along the axis of the spool by counterweights. Metal wire is charged DC with high voltage, about 50000V is the cathode of the device. The metal tube is the anode, surrounds the cathode, and is grounded.

Under the high voltage of the charged metal wire (cathode), it will create a strong electric field inside the anode tube, and when the dust-carrying gas flows through, the gas molecules in the gas stream will be ionized and then transmitted negative charge (electron) to dust particles under impact (bombardment) and/or ion diffusion. As a result, dust particles are attracted to the anode, deposited on the inner surface of the tube and lose their charge, falling into the dust hopper.

In addition, there are many different types of equipment and treatment methods, depending on the characteristics of the waste source to be treated, which will be applied flexibly.

CONTACT INFO:

VIET WATER JOINT STOCK COMPANY

Address: 339 Pham Van Bach, Ward 15, Tan Binh District, City. Ho Chi Minh

Email: Info@vietwaterjsc.com

Website: vietwaterjsc.com – www.moitruongvietwater.com

Phone: 02.862.724.888

Mobile : (+84).0947.9999.30 – (+84).0904.506.065